- Circuit Board Manufacturing SPINDLE

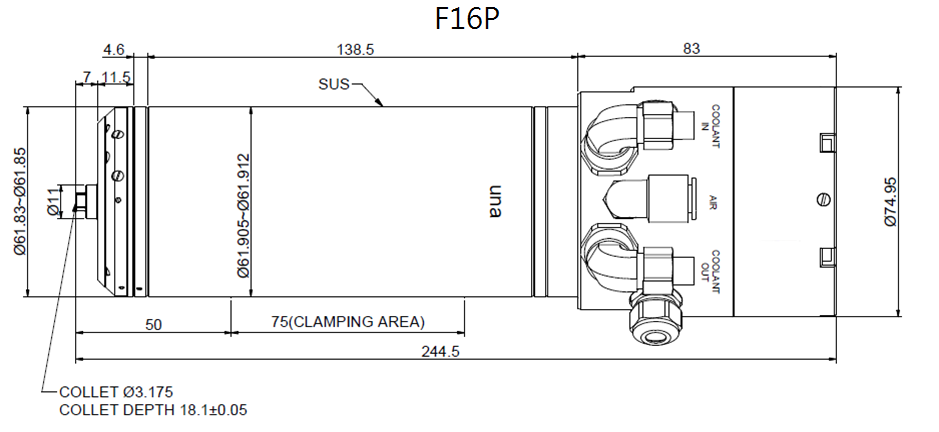

- F16P SPINDLE

- High-speed and high-Torque spindle

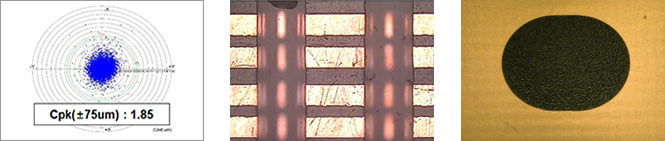

- The 160K RPM high-accuracy and high-speed air bearing spindle is designed to strengthen motor output torque and bearing load capacity, and thus enhance the processing against the materials with large bore diameter and which are difficult to cut, as well as the high-speed processing capacity so that its applicability is greatly enhanced.

|

|||||||||||||||||||||||||||||||

|

| Specifications | |||||||||||||||||||||||

|

Machine Type Link

Machine Type LinkRelated Solutions