Small-Bore Processing Accuracy Upgrading-ATBC Function Modification

After using ATBC can achieve the purpose of improving efficiency-

Improve the bore quality, and further reduce adverse generation, and lower cost.

-

With the accuracy of bore position improved, we can increase the rate of processing, and enhance processing efficiency.

-

So that the machine can be fully utilized for processing of the more sophisticated substrate with high-accuracy required bore position.

-

For processing of the smaller bore diameter (0.2mm below), if the equipped ATBC bush can be used, the quality of micro bore processing will be a greater advantage.

-

Using the equipped ATBC bush on FPC processing, the quality is significantly improved.

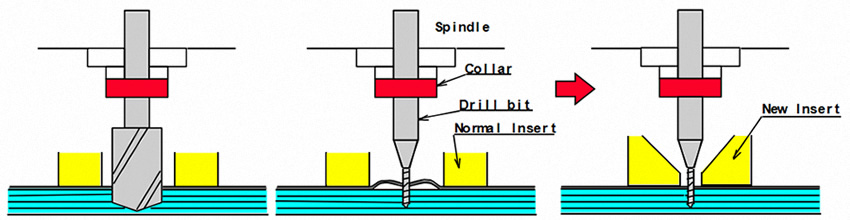

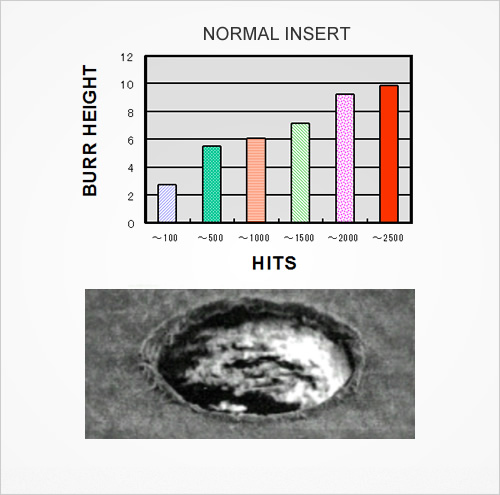

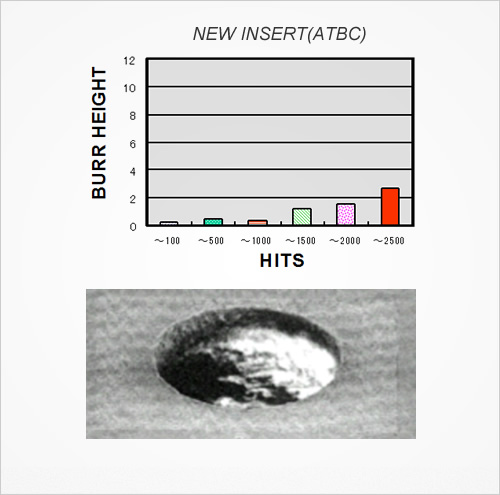

Improve the Quality of Bores Under the same processing conditions, the burring degree beside the hole after using the equipped ATBC bush for processing is better than using the general standard bush.

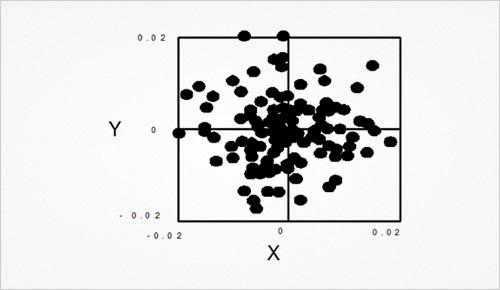

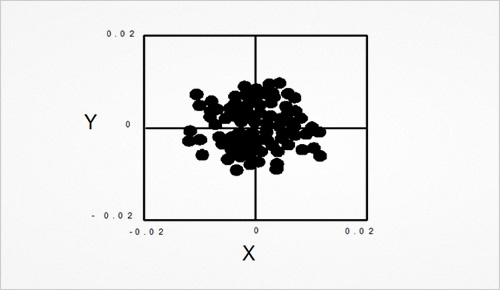

Accuracy Upgrading Under the same processing conditions, the accuracy of bore position after using the equipped ATBC bush for processing is better than using the general standard bush. The bore position is more concentrated and of better stability, after using the equipped ATBC bush in micro bores (less than 0.3mm bore diameter), while the distribution concentration and stability of bore position is poor when using general standard bush.

Pin-Broken Rate Declines The results after test show that the small deformation of Entry material (aluminum plate) greatly affects the micro bore diameter processing, easily causing broken pins and producing other adverse conditions.When using the equipped ATBC bush for processing of micro-diameter drill (below 0.5mm), can reduce deformation of Entry material (aluminum plate), thereby reducing the pin-broken rate, and the production of defective products. .png)

.png)

-